Being able to convey feel to the sound after the keys are played, can transform a performance into something quite unique and almost magical. Indeed, Roland was definitely on to something when aftertouch began appearing on it’s synthesisers in the mid-eighties. Today, many classic synthesisers have aftertouch strips that either don’t work or are a shadow of what they used to be. Almost forty years later, my modern FSR-based replacement aftertouch sensor for the Roland D-50, has considerably more dynamic range and is infinitely more reliable than the second-generation transducers that Roland originally used in the D-50 and transcends the instrument into another dimension.

CONFESSION TIME...

This post was launched on 14th July 2023 but now features my AT-D-50 Mk II which I released today on 1st May 2025. I decided to edit my original post as opposed to creating a new one, as I thought things would simply get confusing.

The latest revision of my AT-D-50 is not technically superior to my original design and functions in exactly the same way. There were however, some issues with my Mk I that I needed to address:

- My original AT-D-50 was time-consuming and hence, expensive to make.

- Packaging was expensive as the Mk I had to be shipped fully assembled and had to withstand transport all over the world.

- It was also expensive to ship again, due to the fact that it was shipped fully assembled.

- Unpacking and handling had to be done with care.

- Installation was challenging. I never had any failures but I felt that things could be made easier.

- I thought it was too expensive and I wanted to bring down the cost for my customers.

Last year, I was inspired to develop several peripherals for the Simmons SDS7. Long story short, I ended up investing in a 3D printer, specifically for 'printing' the internal packaging of one of those peripherals.

Well, I really got into the whole 3D printing thing and soon built up enough confidence to consider other projects, one of them being an idea for an AT-D-50 Mk II. Replacing the rubber platform of my original AT-D-50 with a series of plastic printed strips, could potentially address the issues listed above

Offering a replacement aftertouch sensor for the Roland D-50 in kit form which would comprise several FSR bed pieces on which two FSRs would be mounted, would be much quicker and simpler for me to prepare, easier and cheaper to ship, would pose much lower risk of failure during installation and would be about 25% cheaper.

After the success of my original designs which utilised two FSRs, I contacted several manufacturers but none were willing to supply me with bespoke single FSRs and so I had no option but to continue with my dual FSR configuration. This however, was a blessing in disguise. Had I been able to strike a deal and procure bespoke FSRs, I wouldn't have considered making things compact! That does mean that the AT-D-50 remains a dual FSR system.

The FSR bed strips aren't just simple bits of plastic. At the back of each strip is a ledge so apart from the 'tools' that help accurately align the FSR bed strips relative to the keyboard chassis, it's easy to also accurately align the FSRs. Cool, eh?

My new AT-D-50 comprises three 'common' or universal FSR bed strips and a fourth FSR bed strip which is specific to the respective instrument, in this case, the Roland D-50.

The common FSR bed pieces are just under 220mm long. Although the actual FSRs are much longer, I'm still able to pack everything into something much smaller than my original bespoke shipping box. AT-D-50 Mk II is supplied with a few special plastic strips (tools) that make lining up the FSR bed much quicker, easier and reliable than my old rubber strip system.

SO LET'S TALK FSRS FOR A MINUTE...

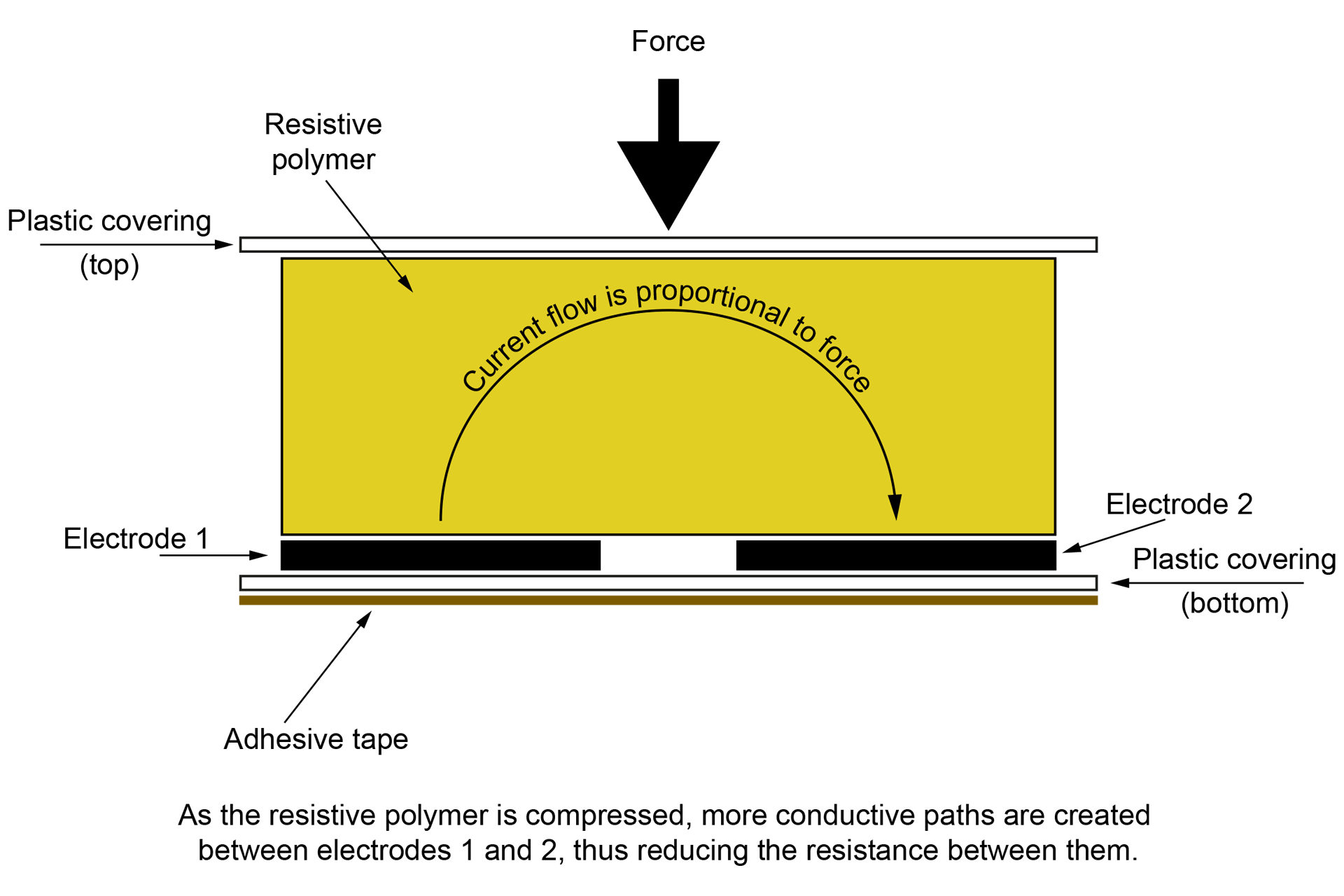

Being basically refined versions of the type of carbon-track sensors that Roland originally used but delivering higher dynamic range as well as other benefits, force sensitive resistors (FSRs) are perfect for this kind of application. In fact, modern aftertouch sensors and even some drum pads use FSRs. The principle is the same but the resistive polymer material is of a modern composition and the manufacturing process makes FSRs considerably more robust and reliable than previous pressure sensors.

OKAY, BACK TO THE STORY...

I get D-50s in all the time so I didn't have to wait too long for a customer to agree that I use their instrument as a test bed for my new design.

Being fundamentally the same as my original design, the only real difference with the new AT-D-50 Mk II is that the FSRs are mounted on several 3D printed strips of plastic instead of a single piece of rubber. The FSRs used are exactly the same. The way that pressure is transferred from the keys to the sensor is exactly the same and the signal sent to the D-50 is exactly the same. The AT-D-50 Mk II is just easier for me to make and ship, cheaper than the original and much easier for you to install.

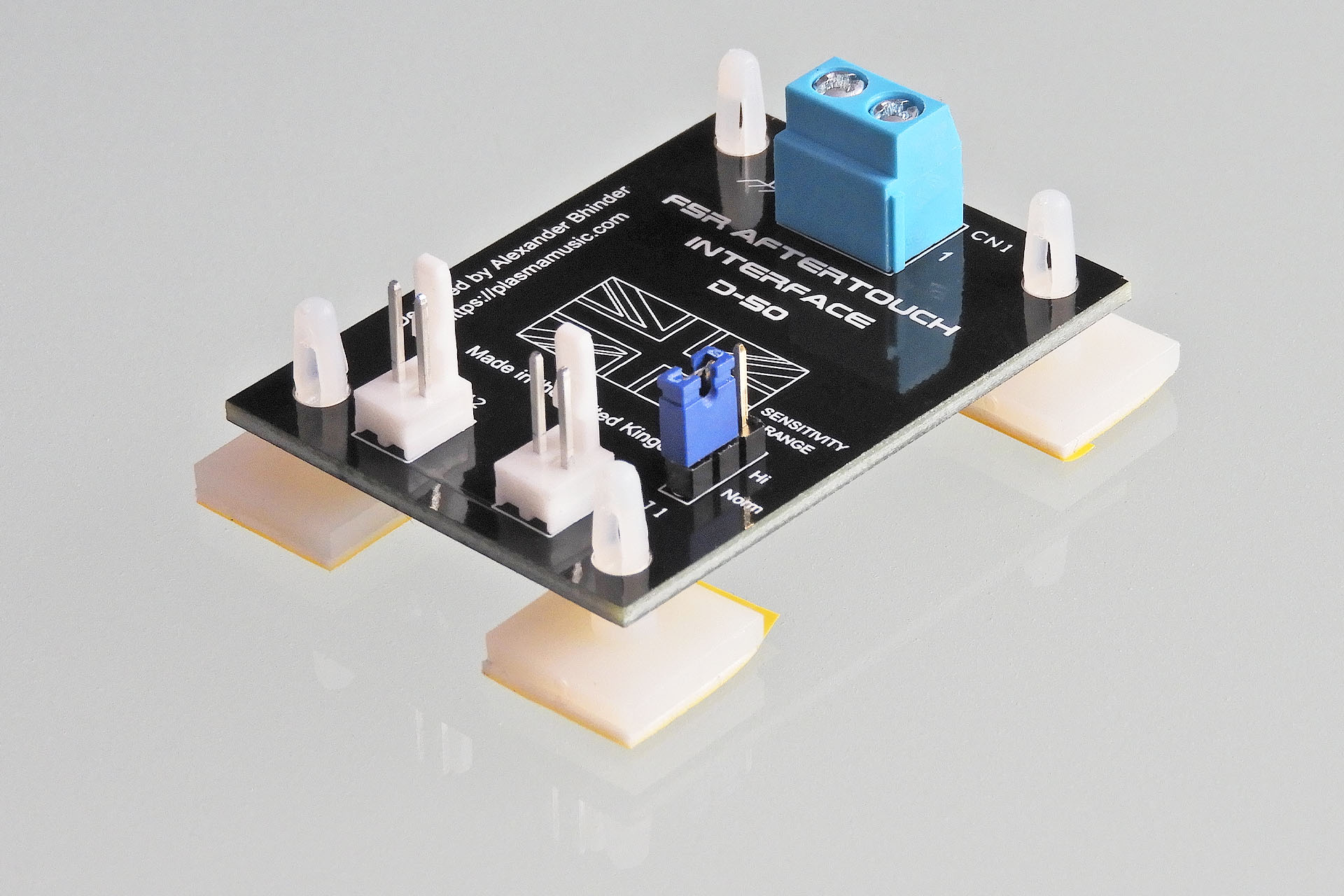

As mentioned and similar to my other FSR-based aftertouch sensors, my AT-D-50 replacement aftertouch sensor for the Roland D-50 comprises two FSRs. The terminals of each sensor are passively summed on a small PCB that I call a FSR Aftertouch Interface or FAI. Of course, FAI is supplied with my AT-D-50.

The output from the FSR combination is quite different to the original carbon-track based system that Roland used in the eighties. FAI compensates for that difference but also offers something else...

FAI provides the facility to select one of two sensitivity ranges. Yes, that's right! What a cool little feature. 🙂 On top of that, the aftertouch control next to the volume control on the top of the D-50 still works as it did before.

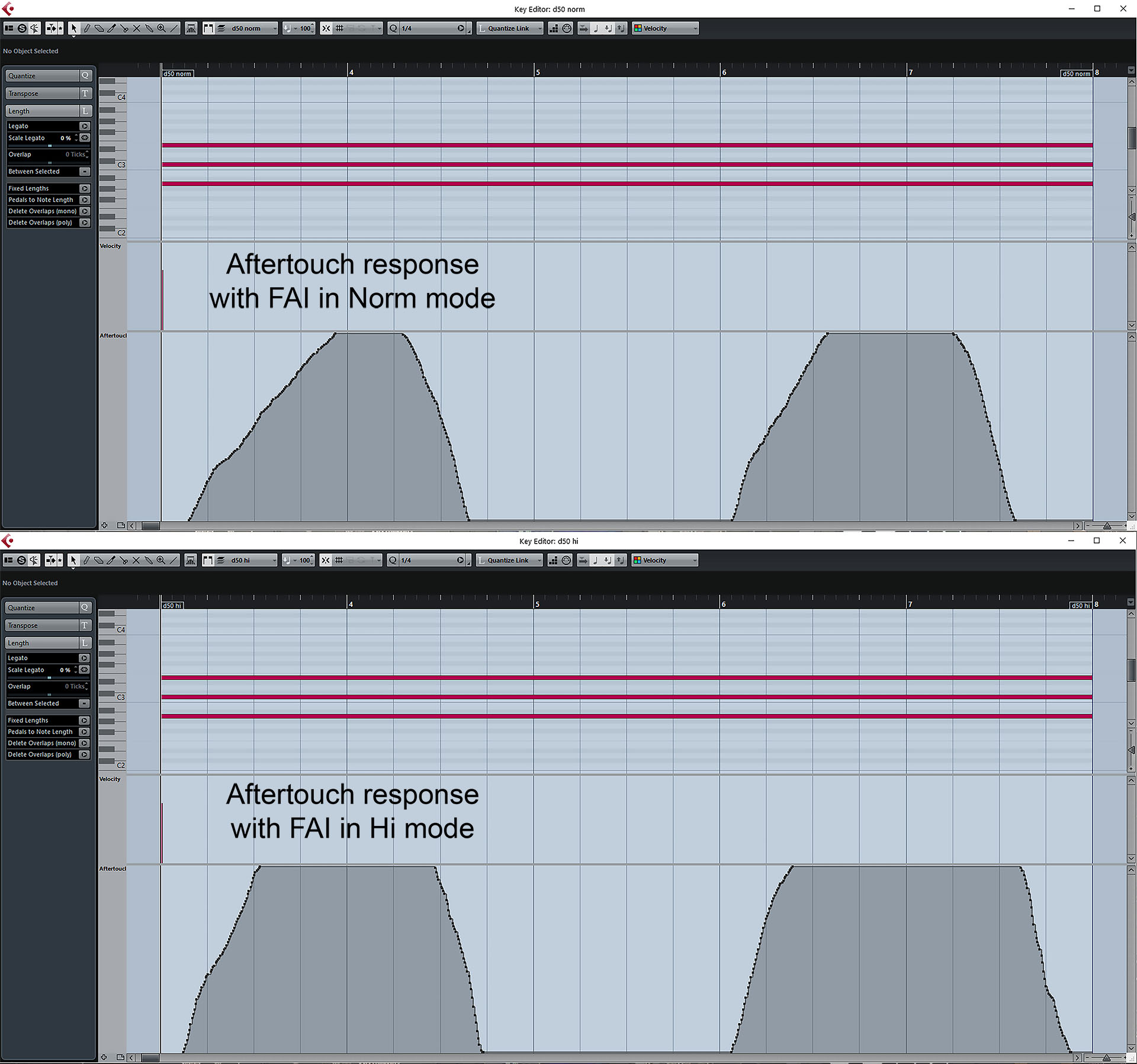

With the aftertouch fader on the D-50 set to about 80%, a MIDI velocity of about 90 and an average pressure, responses were recorded into Cubase with FAI in Norm and Hi modes. As you can see, a MIDI aftertouch value of 127 is reached in both modes. It's just that you get there quicker in hi mode.

Don't forget that you still have control over how aftertouch interacts with each sound within the patch settings.

The 'upside-down' construction (as I call it) of the D-50, means that it's simply not practical to mount FAI to the bottom-case. With so little room on the inside of the top-case, FAI's four self-adhesive feet safely secure it to the inside of the D-50's left side-cheek. I've tried to make things as ergonomic as possible but of course the bottom-case has to be removed to access FAI. Positioning FAI on the inside left side-cheek however, does offer an excellent degree of access to FAI once you're in so switching aftertouch sensitivity ranges in the future, won't be too difficult.

FAI for the D-50 required a redesign of previous versions. Being side-mounted, I decided to use straight (vertical) Molex connectors, for example. It just makes life easier.

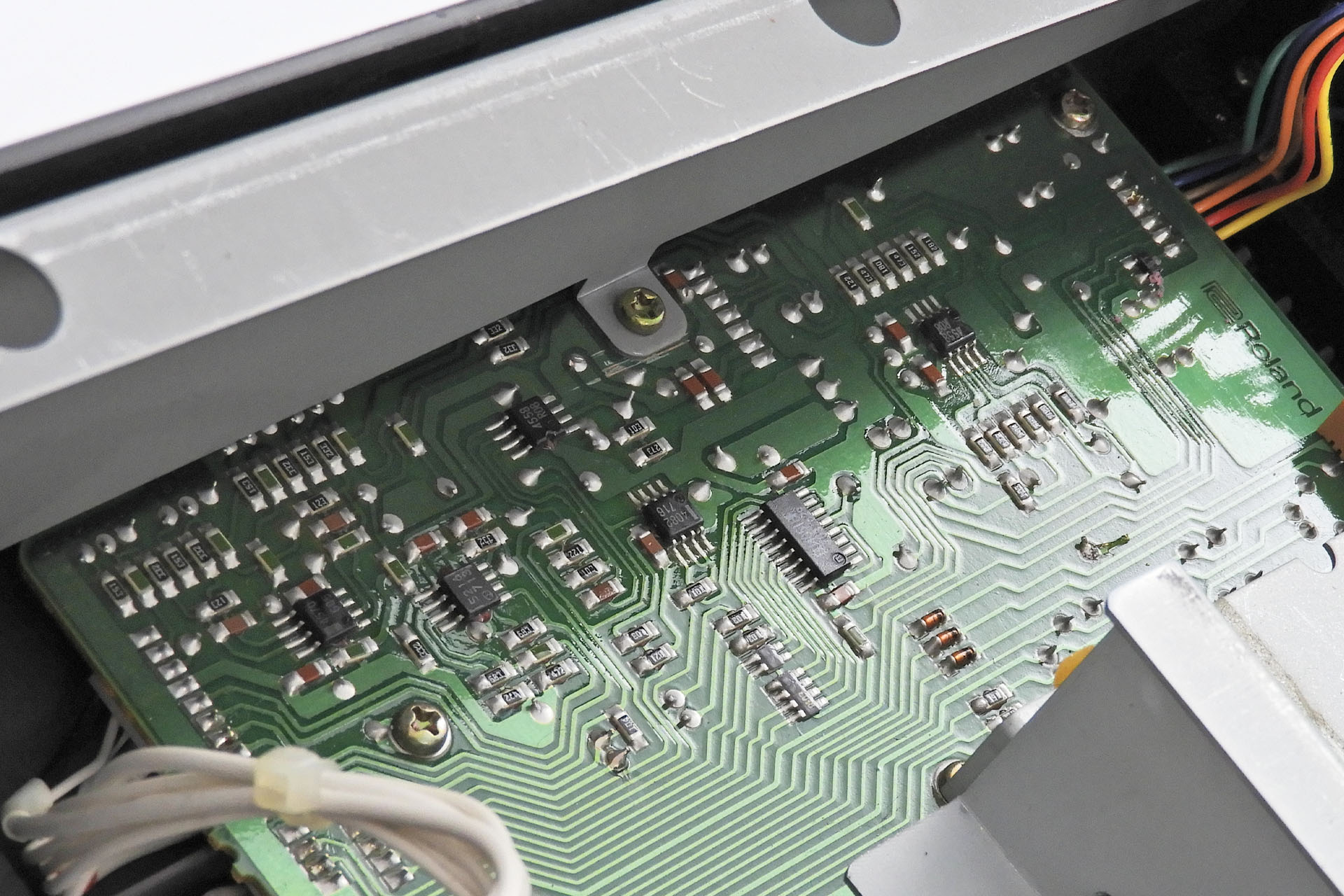

Also, up until FAI D-50, the facility to switch between two aftertouch sensitivity ranges was done by changing the value of the feedback resistor in the aftertouch buffer op-amp circuit. In FAI D-50 however, I decided to do the same job by switching the value of the series resistor between the FSRs and the op-amp.

Remember I mentioned earlier that the D-50 has a lot of passive SMDs? Well one big bonus of adjusting aftertouch gain by varying the series resistor to the buffer op-amp, is that no components on the bender-board need to be replaced. In fact, the bender-board doesn't even need to be removed. All you need to do is solder a two wires to the bender-board.

You've developed an FSR-based aftertouch sensor for one synth (in fact, three) and you think it would be easy to knock up an FSR-based aftertouch sensor for another. Hmmm... not quite. Each synthesiser has it's own challenges and I'm so glad I persevered with this project. I'm delighted that AT-D-50 not just works brilliantly but is now a system which can be installed by anyone with a little patience and technical competence.

I have to admit to being a bit puzzled as to why or how people tolerate an iconic instrument like the D-50, not having aftertouch. Imagine for a moment, that some keys weren't working or if your pitch-bend assembly packed up. Would you just accept it?

With an abundance of sensitivity and very high dynamic range, my replacement aftertouch sensor for the Roland D-50 truly gives this classic synthesiser, a whole new lease of life. It's like suddenly having velocity sensitivity! 😀 The added expression is just magical.

Modern FSRs are very reliable and it's not uncommon to see specifications quoting figures such as 'more than 10,000,000 actuations'. Being sealed units, FSRs are vulnerable to contaminants and oxidation problems like the old carbon-track sensors. It's no surprise then, that modern instruments that feature aftertouch, use FSRs. As previously mentioned, FSRs have a much greater dynamic range than their carbon-track counterparts which makes them ideal for modern drum pads.

I sometimes get asked to provide audio samples but I've backed off from doing that. Aftertouch isn't a sound, it's a feel. You don't 'hear' aftertouch. You hear the effect of aftertouch. So posting an audio file with no reference to how the synthesiser was played, just seems a bit pointless to me. What I can tell you, is that the feedback I've had from users who have installed my FSR systems is humbling and inspiring. For a couple of hundred bucks, it's really worth a shot.

AT-D-50 is available to purchase here: