I try hard to keep my prices as low as possible but quality is equally if not more, important and my philosophy is that there is no point in me doing all of this, if the quality of what I make is not the best I can deliver. I’ve never wanted to be involved with making or selling cheap crap so I've spent quite a lot of time recently, looking into new IEC C14 connectors for Plasma Music power supplies.

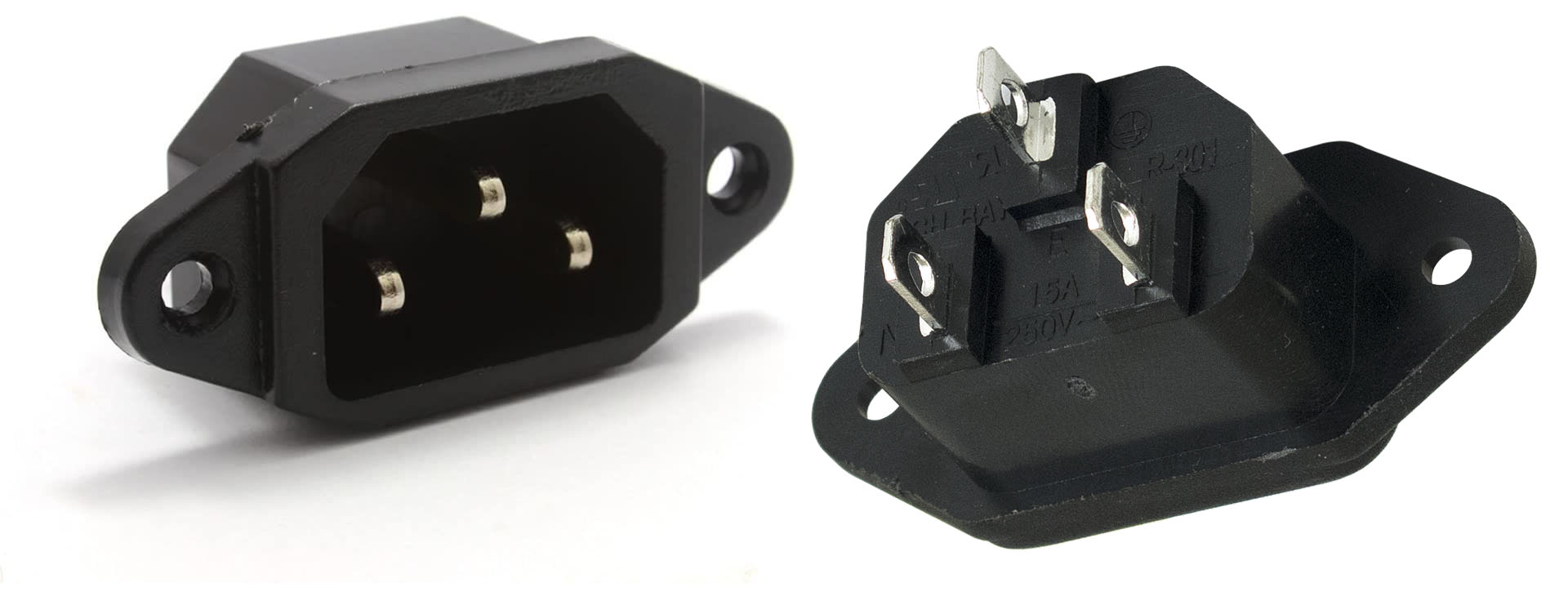

Over the years, I’ve used a variety of IEC C14 connectors but for the power supplies I design and supply specifically for vintage synthesisers, space behind the power inlet socket is often limited. Connectors with 6.3mm (1/4") spade terminals for example, are often quite impractical and so I try to source C14 connectors with shorter solder tags only. Unfortunately, there's not too many to choose from.

Despite changing my soldering iron tip to something a little more heavy duty, I’ve got a bit fed up with just how difficult it can be sometimes, to get solder to adhere to the solder lugs. Quite honestly, if I find it challenging, then I'm concerned for my customers! I’ve therefore, recently changed the make of the chassis mounting C14 connector that I include in my earth bonding kit and that I fit in-place of the now obsolete C10 2-pin IEC connector.

Some may consider that the visual difference between the old and new connectors is perhaps substantial with the newer C14s have a more modern feel about them. More importantly however, they're a better fit for the cut-outs on vintage gear. Hey don't worry, the mounting holes are still 40mm apart! 🙂

Replacement power supplies like Guy Wilkinson's P0004 for the Roland Super JX, my Aurora for the Roland MKS-80 and my Supernova for the Roland Juno-106, all have reduced exposure to mains, making them much safer than Roland's original power supplies. To keep things as safe as possible from the power point of entry, I always fit a boot over the rear of the new C14 chassis mounting socket. This boot is also included with my earth bonding kit.

FOR YOUR INFORMATION

The IEC C14 socket that I use, is a drop-in replacement for the 2-pin IEC connector found on many Roland keyboards and rack modules. It is NOT necessary to drill, file, cut or modify the case to fit this IEC C14 socket.

A little known fact is that even keyboards with integral (hard-wired) power cables, have the power cable mounted to a metal bracket which is secured to the same screws holes and with the same type of screws, that are used on versions with IEC connectors! Behind that plate, is a cut-out for an IEC C14 connector.

Below is an image of the back of a Japanese JX-8P with a hard-wired power cable. You can clearly see that the cable goes into a cable gland which is in a very IEC C14 sized metal plate. T H A N K Y O U, Roland!!!!

99% of the time, the new IEC socket needs to be wired in situ, as it's often soldered to existing live and neutral wires within the machine in question. As such, the easiest, quickest and most reliable solder tags are necessary. Cheaper C14 sockets tend to have heavily plated and quite thick tags which require a lot of heat so as to allow solder to adhere properly. Often made from budget plastic, applying excessive heat can result in the connection pins (which are the other side of the solder tags) becoming loose. That's seriously not good! 🙁 A trick I use to reduce the risk of that, is to plug in a C13 connector into the C14 and then lock the whole thing into a vice.

The new IEC C14 connectors that'll be used on Plasma Music power supplies and that will be shipped as part of my earth bonding kit, will make life easier a lot for my customers but I always welcome feedback so please don't hesitate to contact me with any comments or opinions.