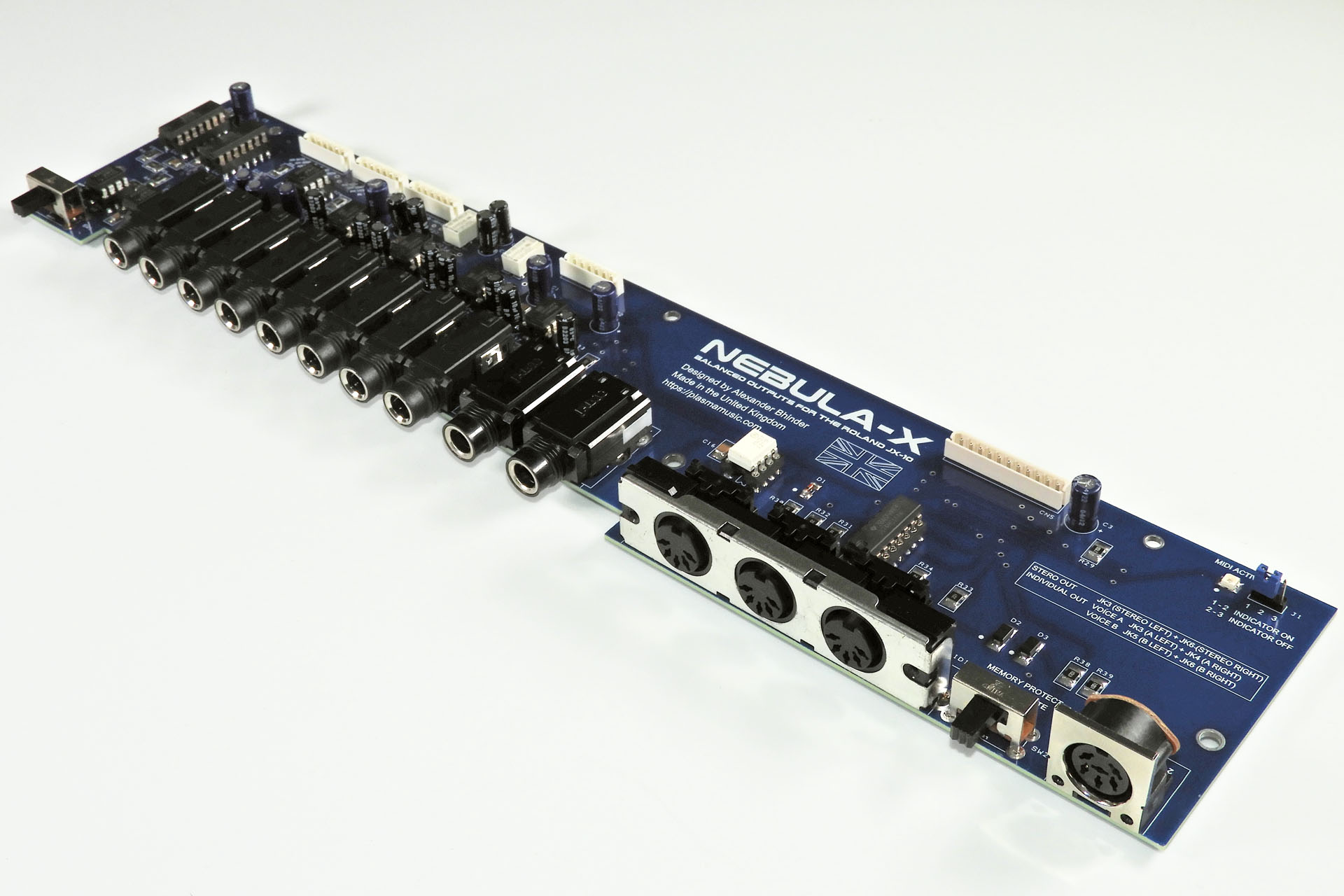

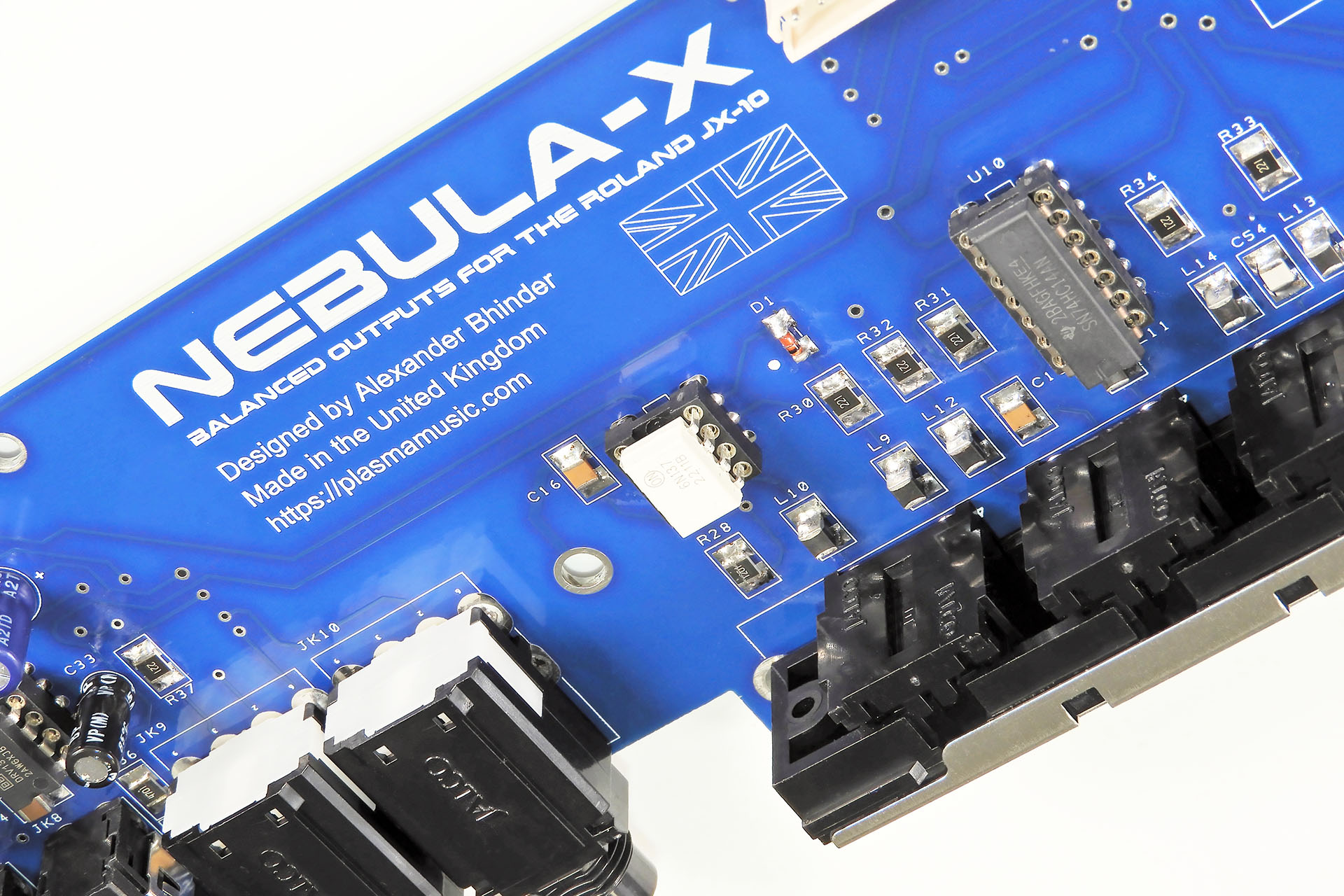

After a few years in the making, I’m delighted to announce that Nebula-X balanced outputs for the Roland JX-10 is finally here.

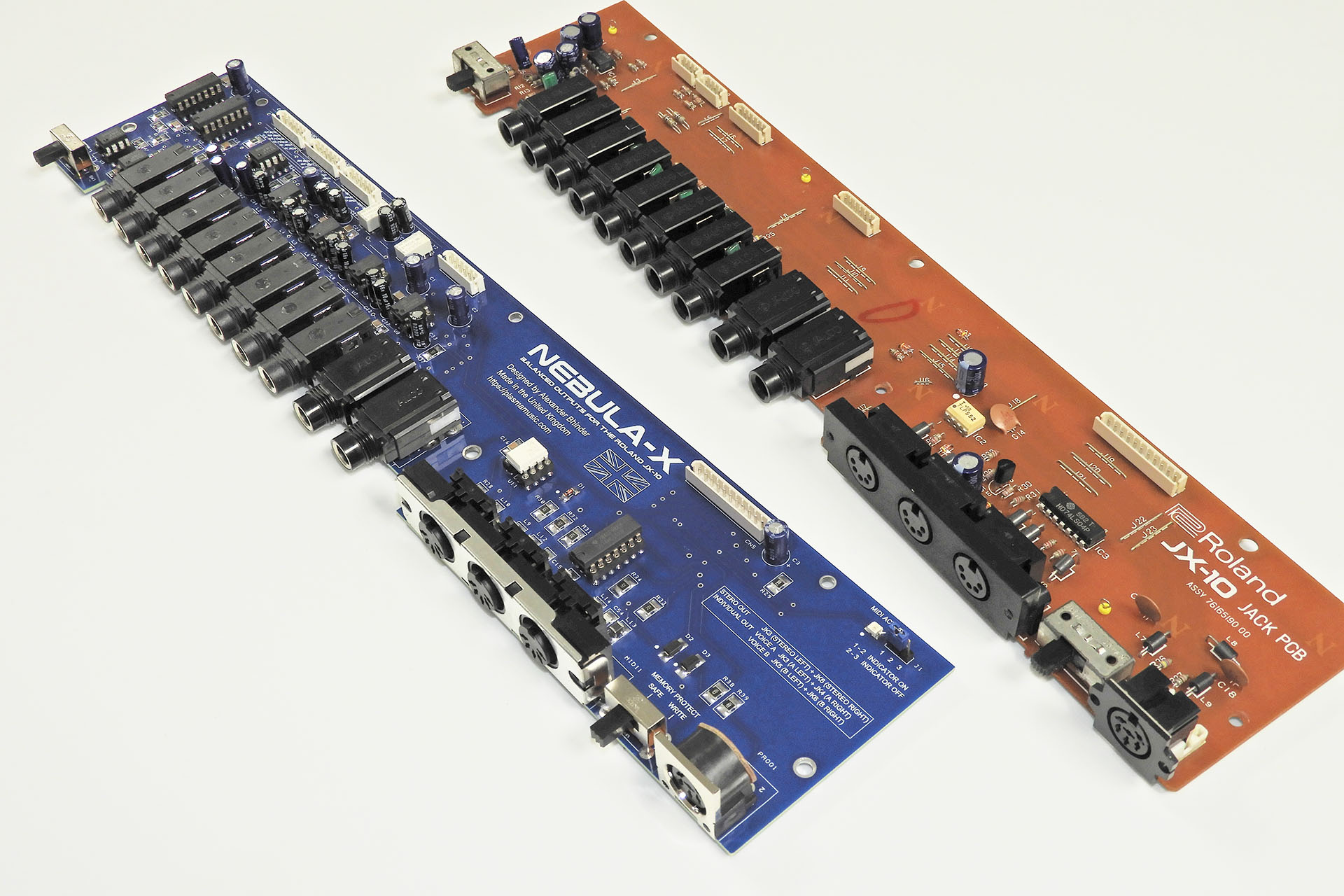

Soon after launching Nebula balanced outputs for the Roland MKS-70 back in Summer 2021, I received enquiries asking if I had plans to do something similar for the Roland JX-10. I took all those enquiries onboard and considered a replacement JX-10 jack-board with balanced outputs but the challenges were simply too much for me to pursue this kind of project at the time.

The JX-10 is a performance synthesiser and as such, it has a lot more sockets than the MKS-70. The JX-10 jack-board also hosts the programmer port and the headphone socket. Oh and one last thing, while I had three MKS-70s, I didn’t have a JX-10! 😒

I continued to receive enquiries and so a version of Nebula for the JX-10 remained in the back of my mind for a couple of years until I had an idea to potentially kill two birds with one stone.

Balanced lines drastically reduce noise between the outputs of one device and the inputs of another. In the JX-10 however, there’s an annoying noise source inside the actual keyboard. The audio connections between the module-boards and the jack-board run straight underneath the very noisy display. Noise picked up by those lines was enough to make Roland use screened cables for those connections, something that wasn’t deemed necessary in the MKS-70, as the layout is quite different. If I could find a way to mitigate internal noise, that would give a replacement jack-board for the JX-10, something that would make a real difference.

So how was I going to achieve a better noise performance? Allow me to digress slightly to explain how this might be possible…

When I was a student in the early eighties and getting my first studio together, the lack of funds often pushed me into thinking outside the box. To reduce noise without balanced lines for example, I used something which I referred to as ‘quasi-differential’ transmission. My mixing desk had balanced inputs but most of my gear didn’t have balanced outputs. Normally, we’d just tie the inverting pin in the connector at the balanced input, to the screen (ground). If however, we use a screened 2-core cable with one core connected to the signal pole of the sending machine and the second core connected to the ground of the sending machine but we don’t join the second core to the screen, then the common rejection feature of the balanced input of the receiving machine would remove noise as if the line was balanced… kind of. Using this principle was in my opinion, something worth experimenting with and suddenly Nebula-X balanced outputs for the Roland JX-10 looked like a worthwhile exercise.

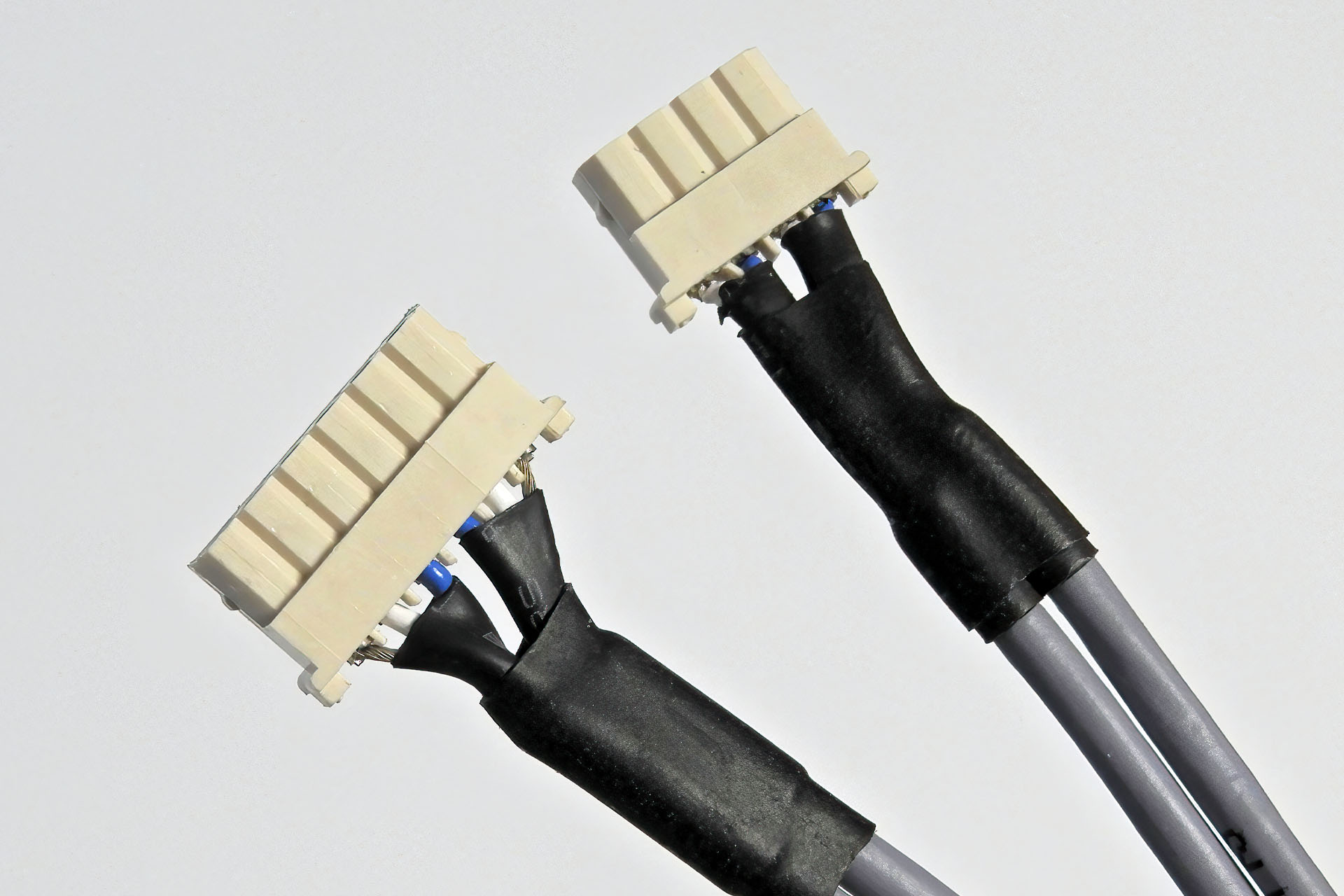

You may have noticed that to do this trick, a screened 2-core cable will be required. Quasi-differential transmission can’t be done with a screened single core cable. Those familiar with the inside of the JX-10 will be aware that the lines connecting the module-boards to the jack-board, are screened single-core cables so YES, new cables will be required but don’t worry, I figured that these should be supplied with Nebula-X.

On top of that, while there’s a 4-pole connector at the mod end of the audio lines in a standard JX-10, the audio connections on Nebula-X are 6-pole as each module-board connection will require two sets of signal, 0V and screen.

This was looking like a really cool solution. Yeah okay, the audio cables will need to be replaced but no modification to the audio output connectors on the module-boards would be required.

So how does this quasi-differential system work?

Well, we kind of use the second core in the cable, the core that's connected to ground at the module-board and goes into the inverting input of one of Nebula-X's differential amplifiers, as bait. We actually want this core to pick up noise!

You see, both the signal carrying core and the 'second' core go into a differential amplifier with the former connected to the non-inverting input and the latter connected to the inverting input. The differential amplifier does its job and rejects, or filters all signals that are common on both inputs. The only common signal is of course, noise since noise hits everything in the same way and doesn't give two hoots if one line is inverting and another is non-inverting.

Do be warned, however. A balanced line CANNOT get rid of noise that's already in the source. Any noise generated on the module-boards for example, won't be filtered out.

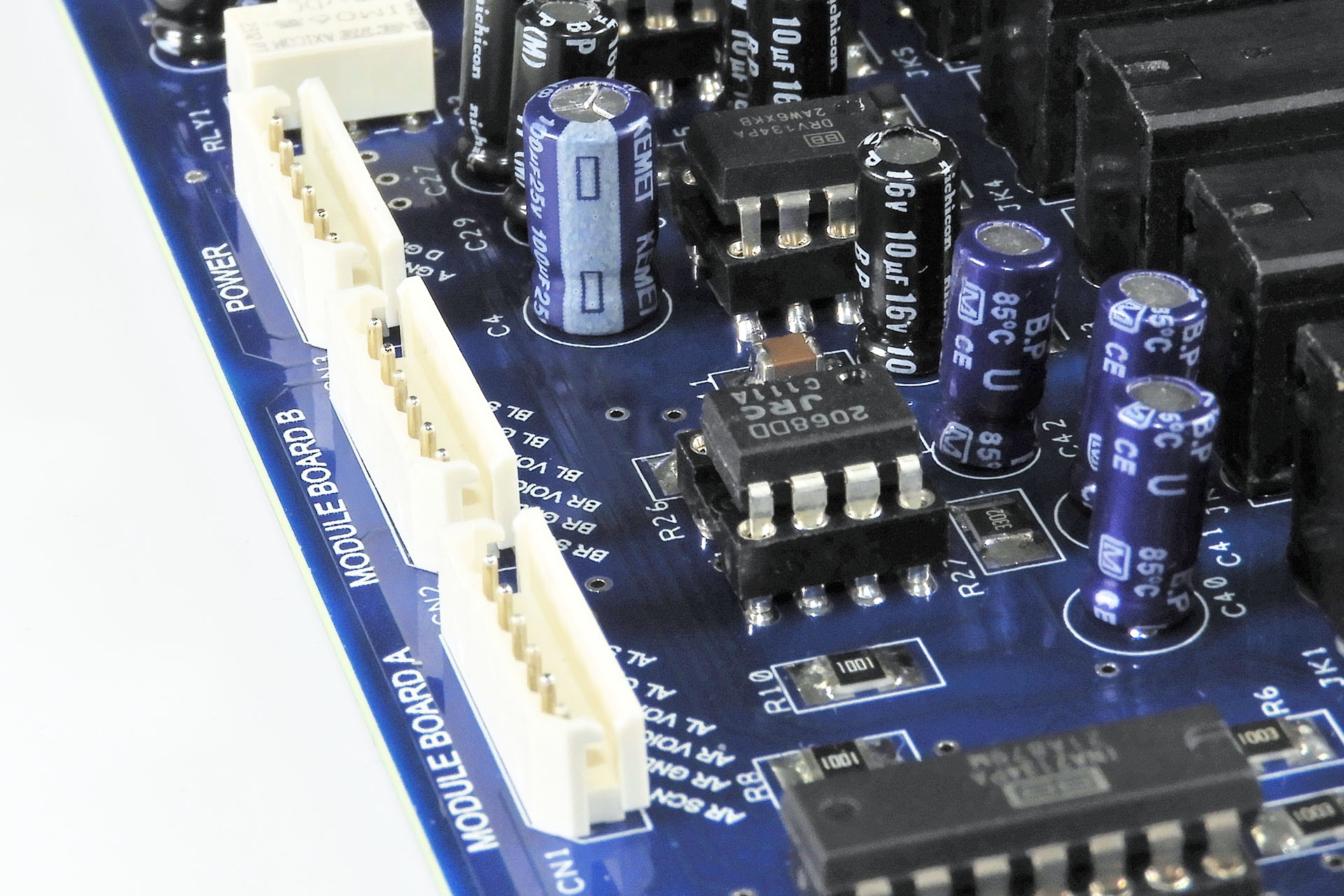

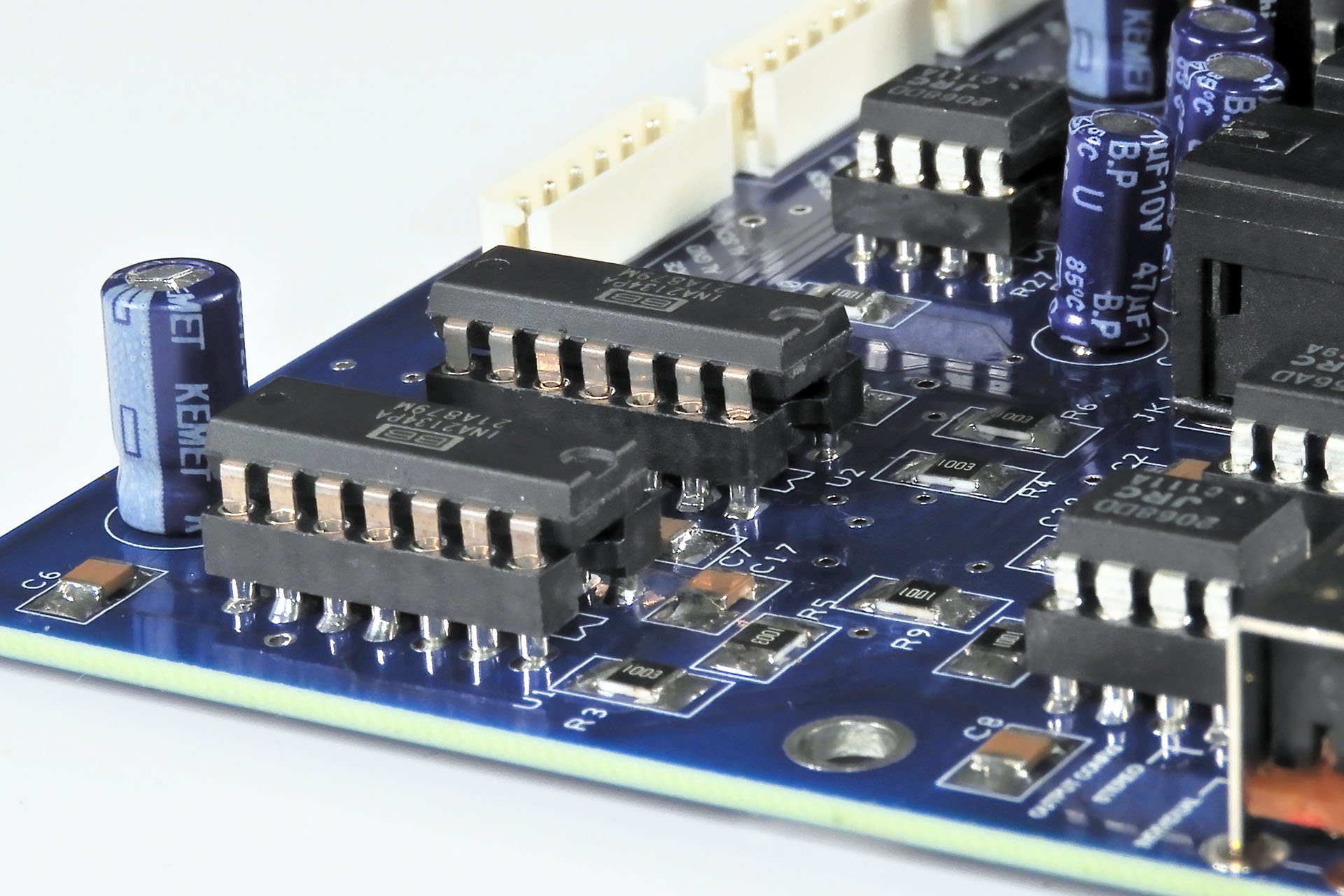

And YES, I'm glad you've worked it out and you’re absolutely correct; to implement my quasi-differential line trick, as well as having balanced outputs, Nebula-X also has balanced inputs. I actually used the INA2134 by Texas Instruments which is an insanely high-specification device.

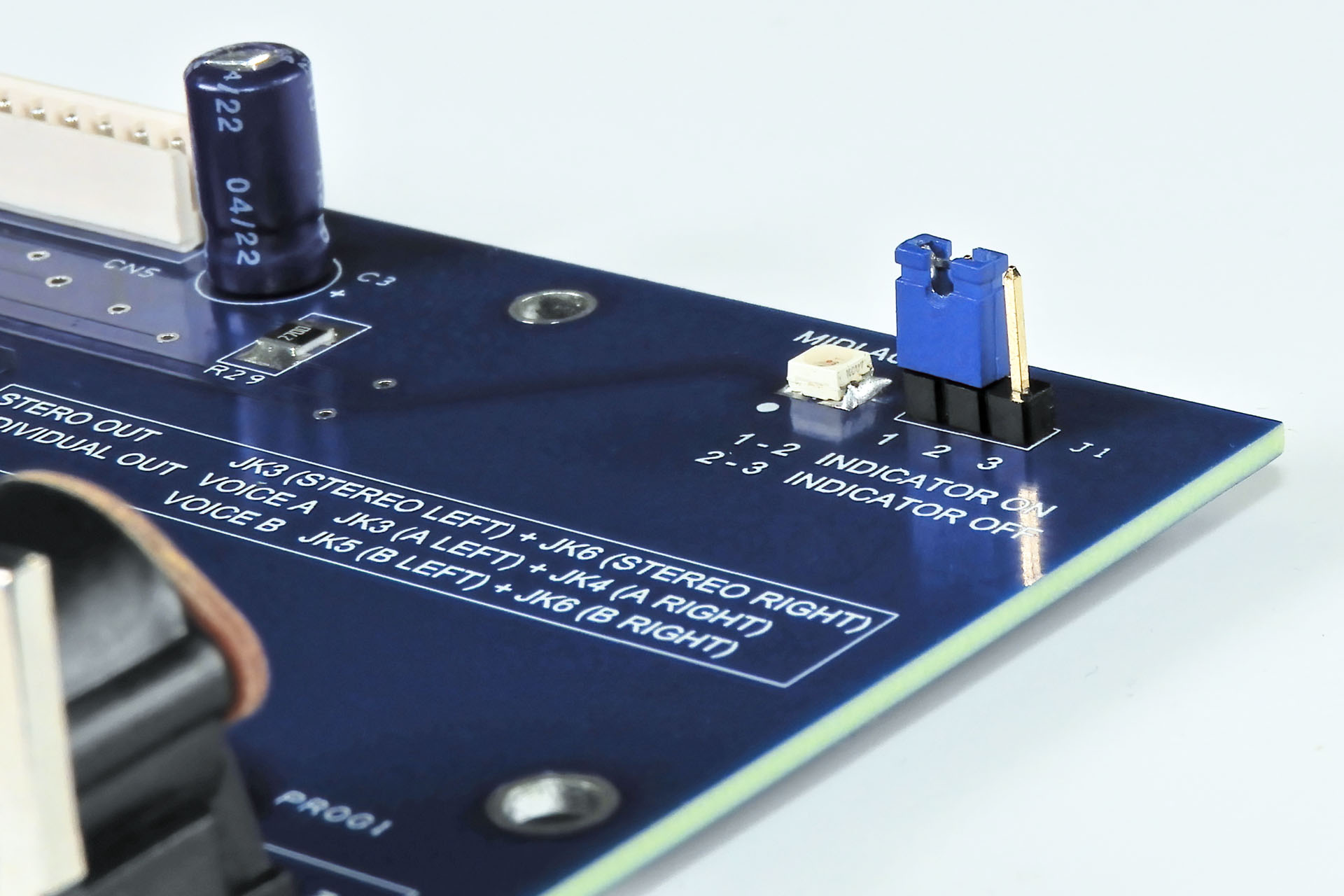

Other than having balanced inputs and a bunch of sockets that aren’t on the MKS-70 jack-board, Nebula-X inherits all the principles that I used on Nebula. Apart from fulfilling the main objective, Nebula-X has revised, more robust MIDI hardware, a MIDI LED indicator (to show MIDI IN) and socketed ICs allowing the user to easily change devices .

Removing the original jack-board can be a bit tricky but with a little patience, it’s far from impossible. A long crosshead screwdriver with a long thin shaft is really helpful.

As mentioned, the original audio lines from the module-boards going to the jack-board, need to be removed or at least disconnected at the module-board ends as well as the jack-board end. The reason I mention that they should at least be disconnected, is that I like my upgrades to be easily reversable. In fact, I absolutely hate the idea of upgrades or modifications that require permanently compromising beautiful vintage equipment and that’s why ALL my upgrades can easily be removed and equipment and respective gear returned to its factory sate.

As with Nebula, designing Nebula-X balanced outputs for the Roland JX-10, required a couple of workarounds which in my opinion, were acceptable compromises.

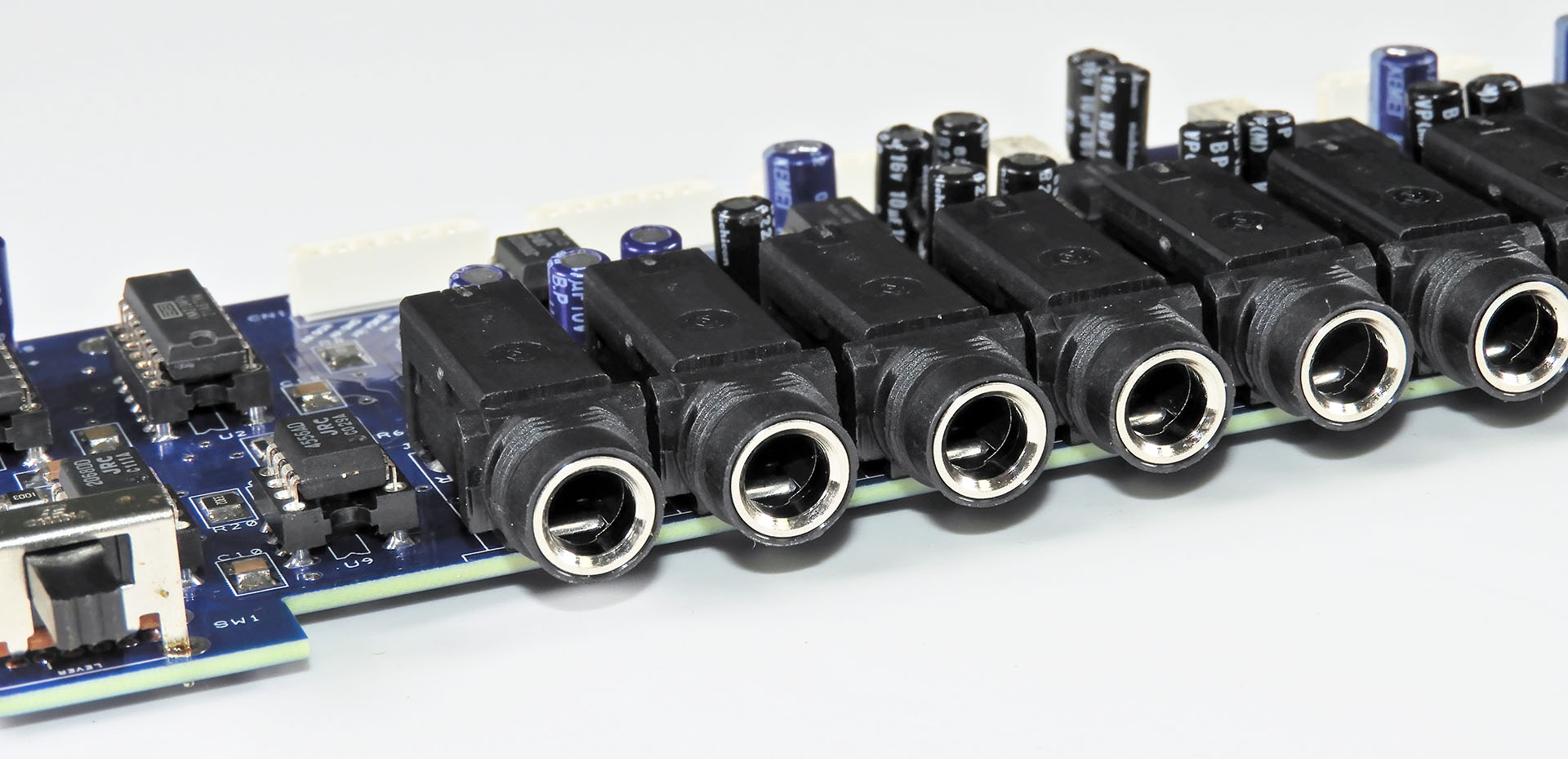

Roland implemented an ingenious switching system which allowed for automatic voice output selection, depending on which output sockets had jack plugs in them. Doing something similar with Nebula and Nebula-X was impossible for one reason and one reason only: space.

As per the original JX-10 jack-board, the pedal inputs on Nebula-X are also switched ‘stereo’ sockets. This is necessary for pedals to work properly and so that the JX-10 switches to C1 and C2 control when no pedals are connected to the jack sockets. Anyway, being much wider than mono switched or stereo unswitched sockets, they simply wouldn’t fit in the locations of the voice-output sockets.

As such, the level selector switch for the mono output has been replaced with a switch that changes the output configuration of Nebula-X from stereo to four independent outputs.

Finding a suitable switch was a challenge which began with the design of Nebula. Something else to bear in mind is that the memory protection switch on the MKS-70 is on the front panel so I didn’t need an ON-OFF-ON (3-position) switch on Nebula. All I needed was an ON-OFF switch to energise a couple of relays to switch the output mode. Nebula-X however, did have to accommodate a memory protection switch.

Unfortunately, despite my best efforts, I couldn’t get an ON-OFF-ON version of the switch I used on Nebula for the MKS-70. 😡 Hence, the memory protection switch on Nebula-X doesn’t have a ‘centre’ (memory protection off) position.

Nebula balanced outputs for the Roland MKS-70 is supplied with a label which goes on the back of the instrument, to remind users of the switch position for stereo and individual outputs.

Similarly, Nebula-X will be supplied with two (smaller) labels for output mode select and memory protection ON / OFF.

One of my philosophies when considering a new design, is to follow the old 80% planning and 20% doing rule. The first thing to consider, is whether or not the new project a worthwhile venture. As mentioned at the start of this post, initially I wasn’t able to convince myself that Nebula-X was worth the hassle. Designing the electronics doesn’t start with a blank schematic. One needs to work out if the new peripheral or modification will work with the host system. Since there are very obvious similarities between the JX-10 and the MKS-70 and bearing in mind that Nebula for the MKS-70 already has a proven track record, it seemed that Nebula-X balanced outputs for the Roland JX-10 would theoretically work.

The mechanical aspects of of a design are also important. There's no point designing cool bit of electronics if for example, it's not going to fit! In the case of Nebula-X, I wanted an easy drop-in design. That’s great but things like screw holes need to line up and sometimes that’s quite challenging when dealing with the types of tolerances in a machine that’s forty years old. Having said that, I do see machines like the Roland JX-10 in a slightly different light. It’s kind of amazing that Roland and other manufacturers were able to achieve such well-fitting panels with the technologies that were available in the eighties.

Indeed, sometimes I feel that the electronics design work of a project is only a small percentage of the work that goes into it. When making peripherals for other manufacturers' equipment, it's important that they should fit. Everything must line up perfectly. A lot of thought went into Nebula-X. In fact, it kind of seems like it should always have been there!

Briefly touched on earlier, finding suitable sockets was another challenge. Size and quality were obvious criteria but what about cost. With no idea how many Nebula-X systems will be sold, I needed to secure a source that will be reliable and offer me realistic prices.

All control port sockets like the two footswitch inputs, the pedal inputs and of course the programmer port, all function as they should.

Roland was keen that their instruments could be used live as well as in the studio so like the MKS-70, the JX-10 has a mono output that can be fed directly into an amplifier. I decided NOT to make this output balanced and set the output level to be compatible with most keyboard amps and combos... not that I imagine anyone taking their JX-10 down the pub for a Friday night gig!

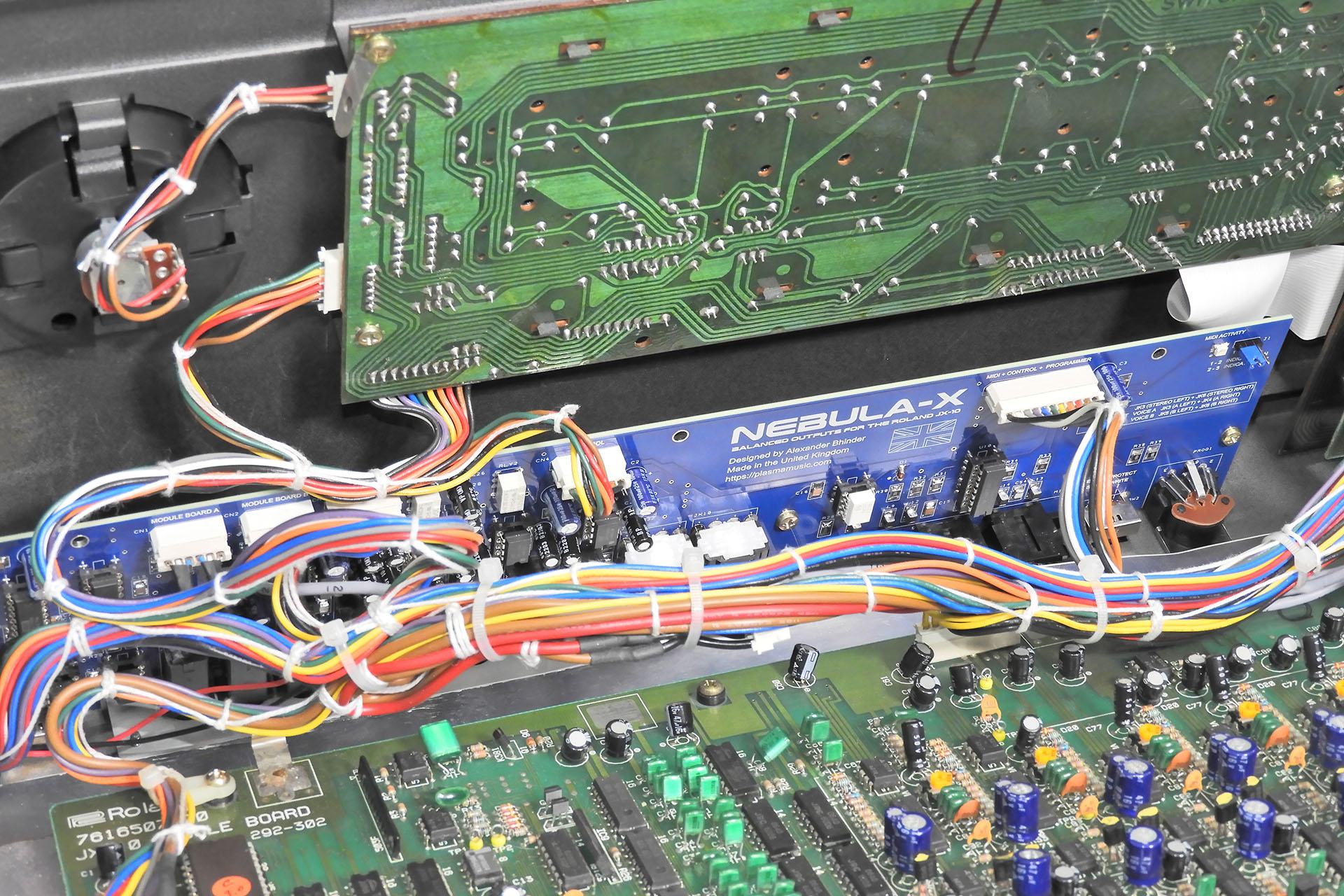

Anyway, after all that, Nebula-X ended up fitting like a glove. Nebula-X literally became a drop-in design, exactly as I had intended and in my humble opinion, Nebula-X balanced outputs for the Roland JX-10 is an easy to install and worthwhile upgrade for the serious JX-10 user.

One last point; balanced outputs are 6dB hotter than their unbalanced counterparts. That can only be a good thing.

All my products are accompanied with either an installation manual or a user guide. Nebula-X is no exception apart from the fact that I haven't written the installation instructions yet! 😕 While I'm getting the test results media together, I'll also be compiling detailed and fully illustrated instructions. Having said that, Nebula-X is pretty straight-forward to install. You just take out the old board and drop in the new. 😎 I guess replacing the two audio cables might be a bit fiddly. With no soldering required, Nebula-X is literally plug 'n' play!

UPDATE: 6th February 2026

NEBULA-X BALANCED OUTPUTS FOR THE ROLAND JX-10 PRE / POST NOISE TESTS

Of course, apart from wanting to satisfy my own curiosity, I don’t expect anyone to take my word for it. Although the theory is sound and indeed, I've used my quasi-differential system many times over the past few decades, I'm quite aware that my word might not be enough. So as soon as I can, I'll be posting some test results. Most likely in the form of a video, I'll record the outputs from my JX-10 with the original Roland jack-board and then with Nebula-X.

Before I show you the Nebula-X noise comparison test, it may be useful to look into the whole JX-10 and balanced line stuff in a little more detail.

Noise and hum from the display, are induced into the cables that connect the audio outputs from the module-boards to the jack-board. Roland tried to reduce the effect of this interference by screening those cables. One wonders just how noisy the JX-10 would have been if Roland hadn’t done that.

Unfortunately, Roland’s attempt to clean things up, didn’t go far enough. One of the objectives of Nebula-X was to see if another approach might do the trick. That approach involves putting my quasi-differential line theory into practice. I’ve already talked about the physical implementation of quasi-differential line theory but understanding a little of the physics, might also help understand my decision to consider this somewhat radical approach.

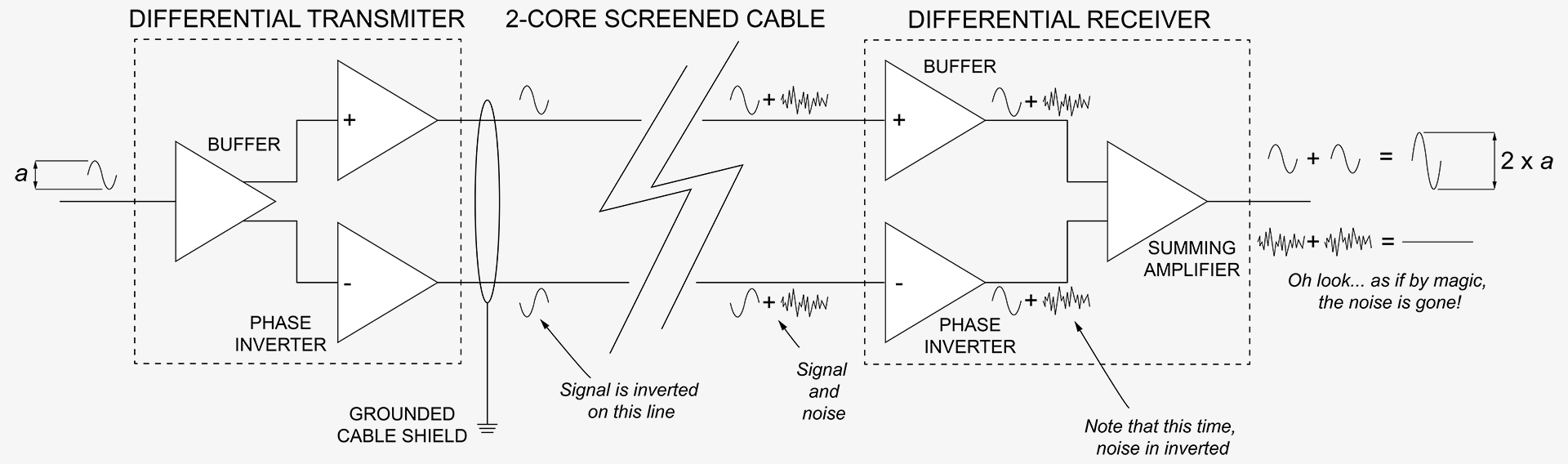

So balanced transmitter sends out tow signals; one is an exact duplicate of the input. The other is also an exact duplicate of the input with one exception, it’s upside-down, or 180° out of phase to the input and hence, also with respect to the other (in-phase) output.

Now let’s look at the transmission line itself. Two conductors carrying the same signal except one’s got the same phase as the original and the other is 180° with the original. Both conductors are in a screen which is usually attached to 0V or ground, at both ends.

Noise and hum induced into the cable that’s carrying the two conductors hits both of those conductors in the same way. The parameter of the noise that we’re interested in, is phase and the phase of the noise on both conductors is the same.

The receiver takes both non-inverted and inverted signals. The non-inverted signal passes though a buffer but just like in the sending device, the inverted signal is inverted again, putting it back in phase with the original signal. Oh but wait a minute… the noise on that line is also inverted and is now 180° out of phase to the noise on the other line.

The next part of the process is to mix the the stuff that's on the two signal lines. When we do this, the noise on one side and now the inverted noise on the other side, cancel each other out. That’s the fundamental theory of balanced line transmission.

In the image above, you may notice something that turns out to be a curious but beneficial side effect of the process and which occurs in the summing of the two lines in the receiver. Since the two lines are summed, the signal that we want ends up being twice the amplitude of the original. This is why a balanced signal is 6dB ‘hotter’ than its unbalanced counterpart. A gain of 2 expressed in decibels 6dB. This important as a Nebula-X in your JX-10 will mean that you’ll need to turn down the gain levels on your mixing desk!

If you stayed with me and got all of that, then you disserve a medal. Well, at least a cup of tea and some cake.

Although the outputs from the JX-10’s module-boards aren’t balanced, we can still kind of use this theory. My quasi-differential system does just that. With a little clever rewiring, we can fool a balanced line receiver into thinking it’s receiving a balanced signal and actually take advantage of the principles described above.

The normally out-of-phase conductor in the Nebula-X system is bait and we actually want it to pick up noise. Doing so means that our balanced line receiver will remove that noise. The downside of using my quasi-differential line theory however, is that summing the non-inverted and inverted lines will NOT yield a 6dB gain. Why? Because our conductor that would be normally carrying the inverted signal isn’t doing that. Instead, it’s connected to 0V on the module-boards. Nebula-X however, has balanced outputs so although there isn’t a 6dB gain on the input, Nebula-X’s outputs are 6dB hotter than the stock Roland jack-board. That’s why I didn’t bother building any gain stages into Nebula-X. The same incidentally, applies to Nebula for the MKS-70.

After finishing Nebula-X and confirming basic functionality and full compatibility with the JX-10, I simply had to get proof that the quasi-differential line theory employed on Nebula-X, actually worked. I was busting to carry out some tests.

Both tests, the first one using the bog-standard Roland jack-board and the second one with Nebula-X, used identical hardware and recording settings with one exception; when testing the JX-10 with the factory jack-board, connection to the mixing desk was via a pair of standard unbalanced cables. When testing the JX-10 with Nebula-X, connection to the mixing desk was via a pair of balanced cables.

Also, don’t forget that for the second part of the test, the two cables inside the JX-10 which connect the module-boards to the jack-board, were swapped out for the special cables that are necessary for Nebula-X to work.

To keep things simple, only the stereo outputs from the Roland jack-board were used and Nebula-X was also set to stereo mode.

The results of the comparison test were as predicted but after some two years of working on this project, they were still most reassuring. You can quite clearly hear a difference, particularly the lack of hum with Nebula-X.

At the end of the test there are a few notes I recorded with both systems. A simple triad playing Super-JX factory patch C-6, with all notes set to MIDI velocity 120, demonstrates the 6dB increase in gain with Nebula-X. For this bit, I dropped the level on Cubase so that you can safely hear the noise test but you won’t bust your monitors when it comes to the notes. No other processing was performed on the tracks. I didn't apply any equalisation, dynamic processing, panning, or any other editing. What you hear is what went in. I haven't even normalised the audio so you you might have to turn up your levels and DON'T FORGET TO TURN THINGS DOWN WHEN YOU'VE FINISHED!

Nebula-X won't change the sound or character of your JX-10.

It'll just give you cleaner and louder outputs.

Nebula-X is available to purchase here...

I'm deeply concerned about the environment and the exploitation of labour and so I always use local manufacturers in preference to the Far East, with the following in mind:

-

- I can be confident that workers are treated fairly and earn a proper wage.

- I can be confident of the standard of quality of each item that is delivered to me.

- Communication is important and using local manufacturers, all correspondence is quick and understandable.

- I believe in supporting the local economy.

- I can be confident that the disposal of manufacturing waste is managed properly and in accordance with national and EU law.

Using local manufacturers isn’t the cheapest option but the above points are important to me. I hope that they’re important to you too.